The main objective of OptiYard is to improve capacity and service reliability by focusing on Yard Operations, namely by providing an optimised decision support system for Yard Managers. Specifically, OptiYard will address the following objectives:

- Automate yard management optimisation: an innovative algorithm to automate and optimise the organisation of the processes to be performed in a marshaling yard will be delivered;

- Real-time interaction with the surrounding railway network: a novel decision support tool for automated ad-hoc timetabling and traffic management to include the yard management in a globally optimised system will be produced;

- Simulate intelligent real-time yard operations: the project will build on a state-of-the-art yard simulation platform compatible with short term innovations, in order to achieve improved modeling and communication system, and to integrate optimised decisions into the real-time simulation;

- Improve information and communication processes: new effective structures for the flows of data towards and from the terminals, necessary for communication and information sharing between infrastructure managers and railway undertakings for yard management will be defined;

- A technical demonstrator in the form of a fully functional software module will be built to show how the developed intelligent real-time simulation can provide concrete and validated optimal decision support for dispatchers in yards, with a link to network management.

OptiYard innovation activities to meet the objective

Impact

The impact of OptiYard is to develop the capacity and reliability of yard operation through enhanced interaction with Network management and decision support tools for optimising the yard resources used and enabling a more efficient train management of the network. At the same time, it results in an improved competitiveness of the operation for which simulation models and optimisation algorithms will be elaborated for this purpose. OptiYard provides improved decision support to optimize operational processes that connect freight traffic in yards and terminals.

The impact will be profitable for:

- Wagon owners by an increased possibility of asset utilisation

- Yard Managers by increasing safety, capacity and efficiency of yard operations

- Infrastructure managers to optimise capacity and planning

- For shippers, with a safer way to handle their dangerous goods

- For shippers with a more reliable freight transport which will enable them to benefit from a more reliable supply chain, thus giving enhanced attractiveness to rail

For the RUs by giving the opportunity to reduce idle time of their assets.

Innovation

Building on the current state of the art and practice, the ambition of OptiYard is to provide a fully functional software module where real-time yard management, interaction with the network and ad-hoc timetable planning will be simulated in real-time. The optimization module and algorithms will be proven for large and complex freight transport networks, and integrate well with IP5 activities towards automation, e.g. intelligent assets and automated shunting and mainline operations.

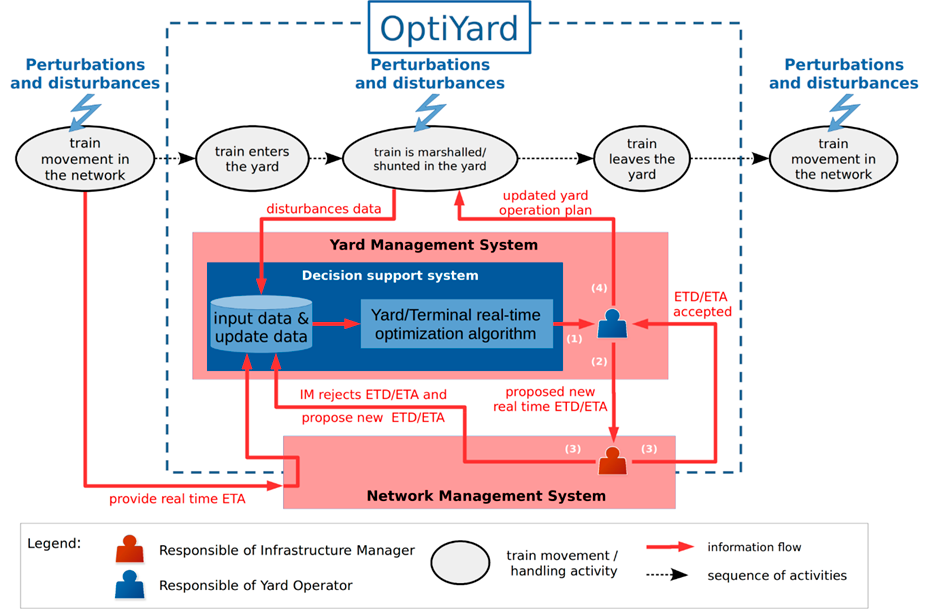

The major innovation and value proposition of OptiYard is illustrated in the following Diagramme:

In current practice, the yard management receives manually transferred information on the progress of the train from the IM. Moreover, information on train composition typically arrives quite late. This forces yard managers to preserve extra resources to face unexpected constraints due, e.g., to the volume and the concentration of arrivals, to operate safely and effectively. OptiYard brings the digital world to yard management. In particular, OptiYard enables:

- Long distance monitoring of incoming trains from the external network on screens enabling to prepare pre-advanced work planning.

- Interaction with the IM to obtain a more accurate ETA as soon as the train enters the relevant network, enabling refined planning. This is done thanks to an algorithm enabling optimised operations and to return a new proposed ETD and ETA to the IM.

- Interaction with IM to find the best possible solution for yard management, train management and the client’s demand.

- Interaction with the IM using real-time optimisation to deal with unexpected events during the approach of the train or the operation in the yard. Thanks to the OptiYard decision support tool, yard management is able to reset a work plan and new ETD and ETA accepted by the IM, thus enabling the client to have accurate updated information on the situation and the future progress of the train.

This innovative approach will enable stakeholders to optimize the use of the network capacity and yard resources whilst enhancing client satisfaction through delivery of accurate and timely information.